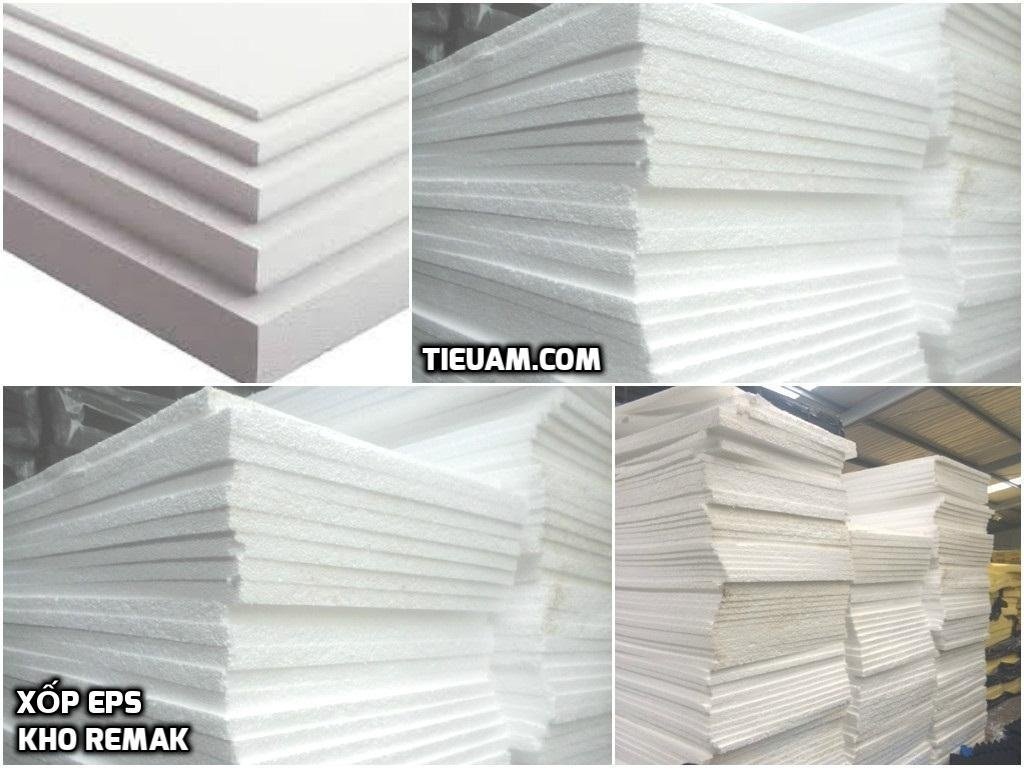

Expanded Polystyrene insulation is a lightweight, rigid, closed cell insulation. EPS is available in several compressive strengths to withstand load and back-fill forces. This closed-cell structure provides minimal water absorption and low vapor permanence.

Hotline:

Expanded Polystyrene foam board insulation is a versatile plastic foam insulation product offering excellent insulation properties at a low cost with a wide range of available thicknesses & densities for residential, commercial & industrial applications such as foundation walls, roofs, pipes or cold storage. The maximum recommended long term exposure temperature is 165°F (74°C).

Expanded polystyrene foam board insulation is available in panels, blocks, custom shapes, tapered board. It has the lowest cost per unit of R-Value compared to all other rigid foam insulation board. EPS contains no CFC's, HCFC's, HFC's, or formaldehyde. It is inert, non-nutritive and highly stable, and therefore will not decompose, decay, or produce undesirable gases or leachates. EPS is recyclable, and safe for WTE Systems and landfills. EPS is 100% recyclable.

The Manufacturing Process

EPS is created in a two-stage process: Raw beads are expanded using steam, creating pre puff beads, which are then cured in large bags before being conveyed to the mold. Once in the mold, the pre puff beads are again steamed to form a block that is anywhere from 37-1/2″ – 54″ x 49″ x 121-1/2″ – 220″. The blocks are then placed on the storage floor to age for the appropriate length of time before being cut into various shapes and sizes. Blocks are produced in several densities to meet specific project needs. Here at ICA we manufacture Low Density EPS foam blocks all the way up to 2.85 lb density.

Environmental Concerns

EPS is extremely “GREEN“. NEVER any CFC’s, NEVER any HCFC’s.

Expanded Polystyrene has always been CFC- and HCFC-free. ICA is an environmentally conscientious manufacturing plant. Our in-house EPS trim is recycled and we accept recyclable EPS from our customers and the public, significantly reducing the amount of EPS that would potentially end up in landfills. In 1994 ICA installed a pentane collection system for air quality control. The system captures the pentane that is released during production and reroutes it through our boiler. This reduces the amount of natural gas we use, saving natural resources while being environmentally responsible. We continued our efforts to be mindful of our environment by installing solar panels and replacing our lighting with energy efficient fixtures. All of these actions help to keep the air of our planet cleaner and lessen the impact of landfills on the population.

EPS Insulation is composed of organic elements – carbon, hydrogen and oxygen – and does not contain chlorofluorocarbons (CFCs) or hydrochlorofluorocarbons (HCFCs).

Benefits:

- Reduces air movements in wall

- Stops dew point / moisture condensation in wall

- Blocks air infiltration

- Resistant to termites, mold and mildew

- Variety of density, thickness, size

- Long lasting, strong stable

- Contains no CFC, HCFC, HFC or formaldehyde

- Recyclable

- Cost effective

Specification:

- Size: 1m x 2m

- Thickness: 2 - 10cm

- Density: 10kg/m3

- Color: white

Features

1. Surface water absorption is low, anti-permeability performance,acid, alkali, salt, oil and other

organic solvents corrosion,

2. Anti-aging performance, good seismic effect,

3. Light weight, anti shock, anti -wet, insulation, anti-noise

Application:

1. Widely used in construction, insulation, packaging, refrigeration,daily necessities, industrial

casting, and other fields.

2. Can also be used to display the venue, cabinets, advertising signs and toys manufacturing,

3. Can be used as a box of filler

For more information, please contact Remak

Hotline: 0902.441.981

Office: Lot10, Lai Yen Industrial Zone, An Khanh, Hoai Duc, Ha Noi

Email: [email protected]